Contractor

Delivering Professional-Grade, High-Quality Mining Equipment

Transportation

Why we are considered the best in business

The core business involves six major sectors: mining operations, mining equipment, engineering blasting, smart mining, overseas distribution warehouses, and financial services.

EPCO Projects

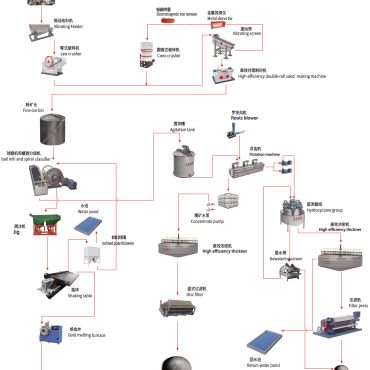

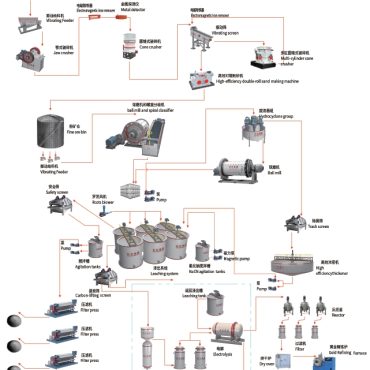

Gold Mining Processes

All Products

-

Technical Highlights:

✓ Adaptive Crushing Cavity – Optimized for various materials and conditions

✓ Durable Wear Parts – Standard manganese steel + optional chromium liners

✓ Advanced Dust Protection – Positive pressure blower extends bearing life

✓ Heavy-Duty Construction – Integrated spindle/moving cone + high-strength frame

✓ Smart Maintenance Features – Wear indicators, no-dismantle bushing replacement, external gear adjustment

✓ Precision Control – Spindle position system for product granularityIdeal Applications:

✓ Hard Rock Crushing – Granite, basalt, iron ore (Mohs 16)

✓ Mining Operations – Primary/secondary crushing stations

✓ Aggregate Production – Quarries and construction material processing

✓ Mobile/Fixed Plants – Balanced design for reduced vibration transmission

✓ Harsh Environments – Dusty or high-wear conditions -

Technical Highlights:

✓ Robust Construction

High impact resistance and stability

Heavy-duty guard plate protects jaw body and bearings

Symmetrical “V” crushing cavity with large inclination angle

✓ Advanced Adjustment System

Mechanical/hydraulic discharge outlet adjustment (faster & safer)

Synchronized frame-motor movement for auto belt tensioning

✓ Optimized Performance

Larger feed size capacity

Higher yield with uniform particle size

Reduced jaw plate wearExtended operating time with convenient lubrication

Ideal Applications:

✓ Primary Crushing in mining/quarrying (hard rock, ores)

✓ Aggregate Production (high-yield processing)

✓ Recycling Operations (durable for tough materials)

✓ Mobile/Stationary Plants (low downtime & easy maintenance) -

Technical Specifications

✓ Power Range: 75-800kW

✓ Throughput: 5-150TPH

✓ Max Feed Size: ≤25mm

✓ Fineness Adjustment: 45-200μmKey Innovations

• Dual-mode grinding technology

• Adaptive media optimization

• Low-wear lining system -

Technical Highlights:

✓ Optimized crushing cavity – Laminated design boosts capacity (+20%) and improves particle shape

✓ Reliable transmission – Spiral bevel gears + anti-adhesion bearings enhance durability

✓ Smart protection – High-pressure hydraulic margin enables overload alerts

✓ Dust-proof lubrication – Positive pressure system extends oil/equipment life

✓ Space-saving – Integrated hydraulic+lubrication stationIdeal Applications:

✓ High-yield aggregate production

✓ Shape-sensitive material processing

✓ Continuous mining operations

✓ Dusty/harsh environments -

Applications:

✓ Metal/non-metal mineral processing

✓ High-volume ore production

✓ Environmentally-sensitive operationsKey Benefits:

• 40%+ energy savings

• Extended equipment lifespan

• Reduced maintenance costs

• Compliant with green production standardsPerformance Features:

High processing capacity

Wide material adaptability

Stable long-term operation

Optimal resource utilization

-

Operational Benefits

✓ 30% higher efficiency than traditional crushers

✓ Lower energy consumption per ton processed

✓ Reduced maintenance requirements

✓ Adaptable to various material hardness levelsIdeal Applications

Cement plant raw material preparation

Glass recycling operations

Aggregate production from river pebbles

Mineral processing operationsTechnical Specifications

Material Hardness: Medium-hard (Mohs 4-6)

Drive System: Single drive configuration

Pressure Adjustment: Mechanical spring with auto-regulation

Special Features: Uniform-wear roller technology -

Technical Specifications

✓ Capacity Range: 20-300TPH

✓ Maximum Feed Size: ≤300mm

✓ Power Options: 15-132kW

✓ Noise Level: <75dB -

Technical Highlights:

✓ Fixed spindle – Compact, high-efficiency design with strong load capacity

✓ Smart oil monitoring – Temperature sensor ensures stable operation

✓ Quick maintenance – Thickened cone wall + improved liner fixing for fast replacement

✓ Advanced lubrication – Integrated hydraulic + thin oil system extends lifespan

✓ Superior hydraulics – Large oil pipe + accumulator for better buffering

✓ Optimized crushing – Inter-particle lamination boosts fines (+30%) and reduces wearIdeal Applications:

✓ High-capacity mining

✓ Fine aggregate production

✓ Low-maintenance operations

✓ Harsh environment crushing

All News

Loraic Air freight service deliver the knowledge & opportunity to optimize every mile on every lane. Get full-service